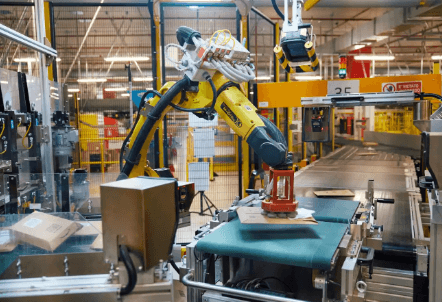

How Robotics Are Changing Manufacturing Forever

Robotics are fundamentally transforming manufacturing processes through increased automation, precision, and adaptability. They enable continuous operation, reduce human error, and enhance safety by handling hazardous tasks. These technological shifts also support rapid customization and modular designs, prompting a reevaluation of workforce roles. As these changes accelerate, understanding their long-term implications becomes essential for maintaining competitiveness and fostering innovation within the industry.

Enhancing Efficiency and Productivity

The integration of robotics into manufacturing processes significantly enhances efficiency and productivity by enabling continuous, high-precision operations that reduce cycle times and minimize human error.

Smart assembly systems optimize workflows, while predictive maintenance anticipates failures, maximizing uptime.

This synergy empowers manufacturers to pursue operational freedom, fostering innovation through autonomous, adaptive, and resilient production environments.

Improving Safety and Reducing Risks

How does the integration of robotics fundamentally enhance safety and mitigate risks in manufacturing environments? Robotics enable advanced hazard prevention through precise monitoring and real-time response, significantly reducing accidents.

Their automation of dangerous tasks minimizes human exposure, fostering a safer workspace. This evolution promotes accident reduction and ensures operational resilience, empowering manufacturers with safer, more resilient production systems.

Enabling Customization and Flexibility

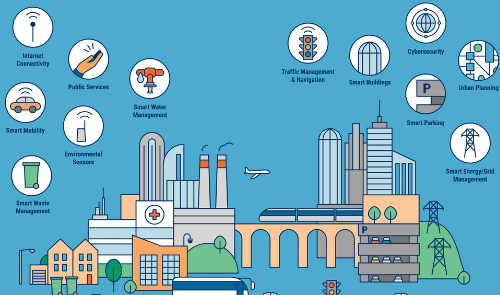

Robotics significantly advance manufacturing flexibility by enabling rapid adaptation to diverse product specifications and volumes. Modular design facilitates swift reconfiguration of systems, while adaptive automation dynamically adjusts processes in real-time.

This synergy empowers manufacturers with unprecedented customization capabilities, fostering innovation and responsiveness, and ultimately expanding creative freedom within production environments.

Transforming Workforce Dynamics

In what ways are robotic advancements reshaping workforce dynamics within manufacturing environments? Robotics are transforming the labor market by automating routine tasks, prompting a shift toward advanced skill development. This evolution fosters a more adaptable, innovative workforce, enabling workers to focus on complex problem-solving and strategic roles, thereby supporting greater operational freedom and economic resilience.

See also: gagnant-turf.ne

Conclusion

As robotics increasingly integrate into manufacturing, their dual role in optimizing efficiency and enhancing safety becomes evident. The convergence of modular customization and adaptive systems fosters unprecedented flexibility, while workforce evolution aligns with technological advancements. This synergy signals a transformative era where innovation intersects with operational resilience, suggesting that the continued evolution of robotics will fundamentally redefine manufacturing paradigms—an inevitable progression driven by the precise, reliable, and adaptable nature of robotic automation.